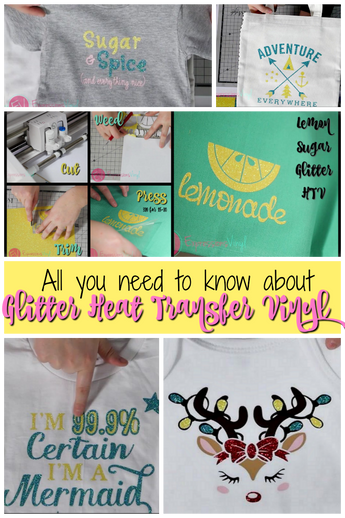

Heat transfer vinyl is a special type of vinyl that can be cut on the silhouette cutting machines which can then be applied to fabric be it clothing pillow covers bags etc with heat and pressure.

Silhouette heat transfer vinyl not sticking.

Siser easyweed heat transfer vinyl available in sheets or 12in by 10ft.

I have a step by step tutorial on how to make a custom t shirt.

I have an easy tutorial on how to use heat transfer vinyl htv.

We recommend using a piece of light weight fabric between the iron and the heat transfer.

Then if you d like repeat the same process with a smaller version of this design in a different color.

The best heat transfer vinyl for cricut and silhouette is.

For flocked foil and glitter vinyl i cut it at a depth of 33 and speed of 8.

If your heat transfer vinyl does not stick to your fabric you ll need to iron it for a little longer.

Youc an use a heat press or an iron although a heat press is highly recommended if you re doing a lot of htv projects or selling at all.

Use an iron or a heat press to adhere the heat transfer.

Transfer not sticking to the garment.

That is peel off the extra heat transfer and leave your mirrored design on the clear backing 6.

When too much pressing happens on a design it is almost as if the adhesive gets completely burned off.

After the design is weeded place it on your desired surface.

On the other hand if easyweed is not pressed long enough or at too low of heat it will also not.

With my silhouette cameo i cut smooth heat transfer vinyl at a depth of 13 and speed of 10.

When it is sticking to your fabric go ahead and slowly pull off your clear backing.

From designing to cutting to applying.

Peel off the transfer sheet.

I use a regular blade for both.

I ll cover the best heat transfer vinyl to use for shirts and how to make your own transfer.

Okay so which is my favorite.